Petrochemicals, which are chemicals made from petroleum and natural gas, are used to make almost all of our plastic products. Such a high volume of petrochemicals are produced to meet our voracious demand for plastics that, as anyone with eyes can see, our environment is severely affected. Oil spills impact the land and waters, and the emissions from burning fossil fuels cause damaging smog, pollution and fricking CLIMATE CHANGE.

Even in America, where we do a pretty good job of keeping trash in the cans, when was the last time you went to a beach and saw it was completely litter free? The reality is that there isn’t really anywhere that’s litter free anymore.

Scientists and other environmental experts tell us that in order to reduce the harmful effects of petrochemicals, we have to reduce our consumption. The problem is that petrochemicals are everywhere – including in almost all disposable flatware and drinking straws we use.

Photo Credit: Hoitintungs CC BY-SA 3.0

But a Mexican company has developed an ingenious product to try and tackle the problems our rapacious consumption causes for the environment.

As a chemical engineering student with a passion for solving environmental problems caused by pollution, Scott Munguia was already working with the raw properties of mango pits and mamey sapote seeds. Then he read a paper that showed an image of the corn molecule used in making bioplastic. He realized the similarities between that molecule and a molecule found in avocado seeds.

Photo Credit: Pxhere

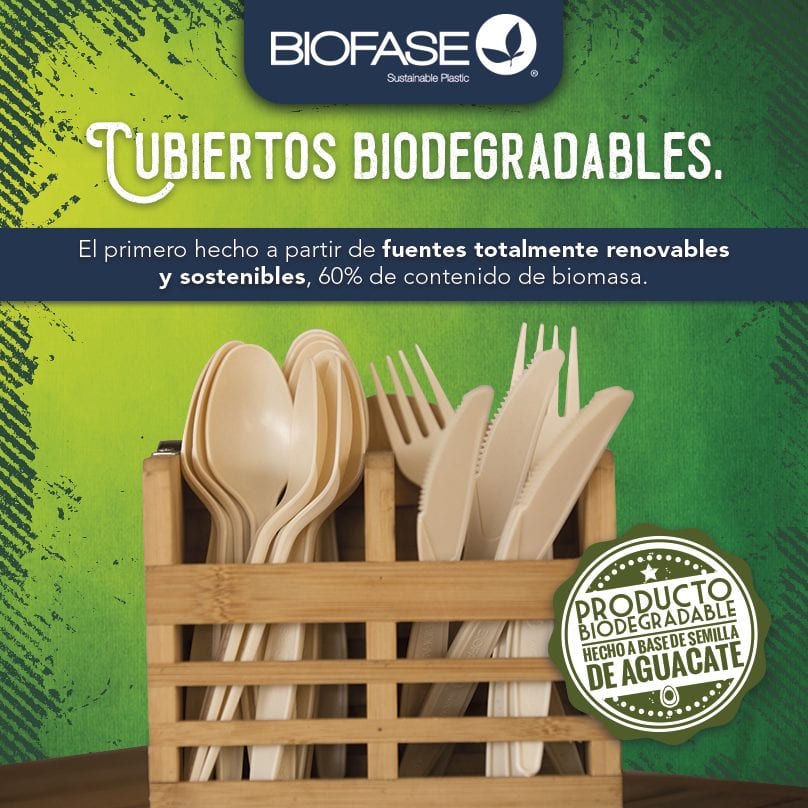

After two years in development, Biofase was born in 2013. By 2015, Munguia’s first plant, based in Morelia, Michoacan, began manufacturing 100% biodegradable and ecologically-friendly plastic resins as raw material. He moved into manufacturing his own plastic flatware and straws in a second plant.

His future plans include another plant with a capacity of 700 tons of material per month. With Mexico growing 300,000 pounds of avocados a year, there’s no shortage of seeds. Bioplastics News reports the global market for bioplastics is now at $5.8 billion.

Photo Credit: Facebook

The positive impact of Munguia’s innovation is steadily gaining attention. Munguia’s bioplastics degrade after 240 days of exposure or burial. Plastics made by petrochemicals can take more than 100 years to break down. Taking avocado seeds and making them into bioplastics also keeps them from piling up in Mexican landfills – it takes what was formerly treated as waste, and uses it as a raw material.

His biggest customers are chain restaurants like P.F. Chang’s China Bistro and Chili’s Grill & Bar. The plant in Morelia produces 130 tons of plastic products (straws make up about 40% of this yield) that are exported to the United States, Canada, Costa Rica, Colombia and Peru.

I don’t know about you, but I’d feel a whole lot better about throwing my disposable fork in the trash if I knew it wouldn’t stick around to say hello to my great-grandchildren.