Men (and presumably some women) have been using shape-edged tools to shave the hair from their skin for millennia.

I had no idea that cavemen also used to prefer a clean shave to stubble, but according to the Discovery Science Channel series “How It’s Made,” that’s exactly right.

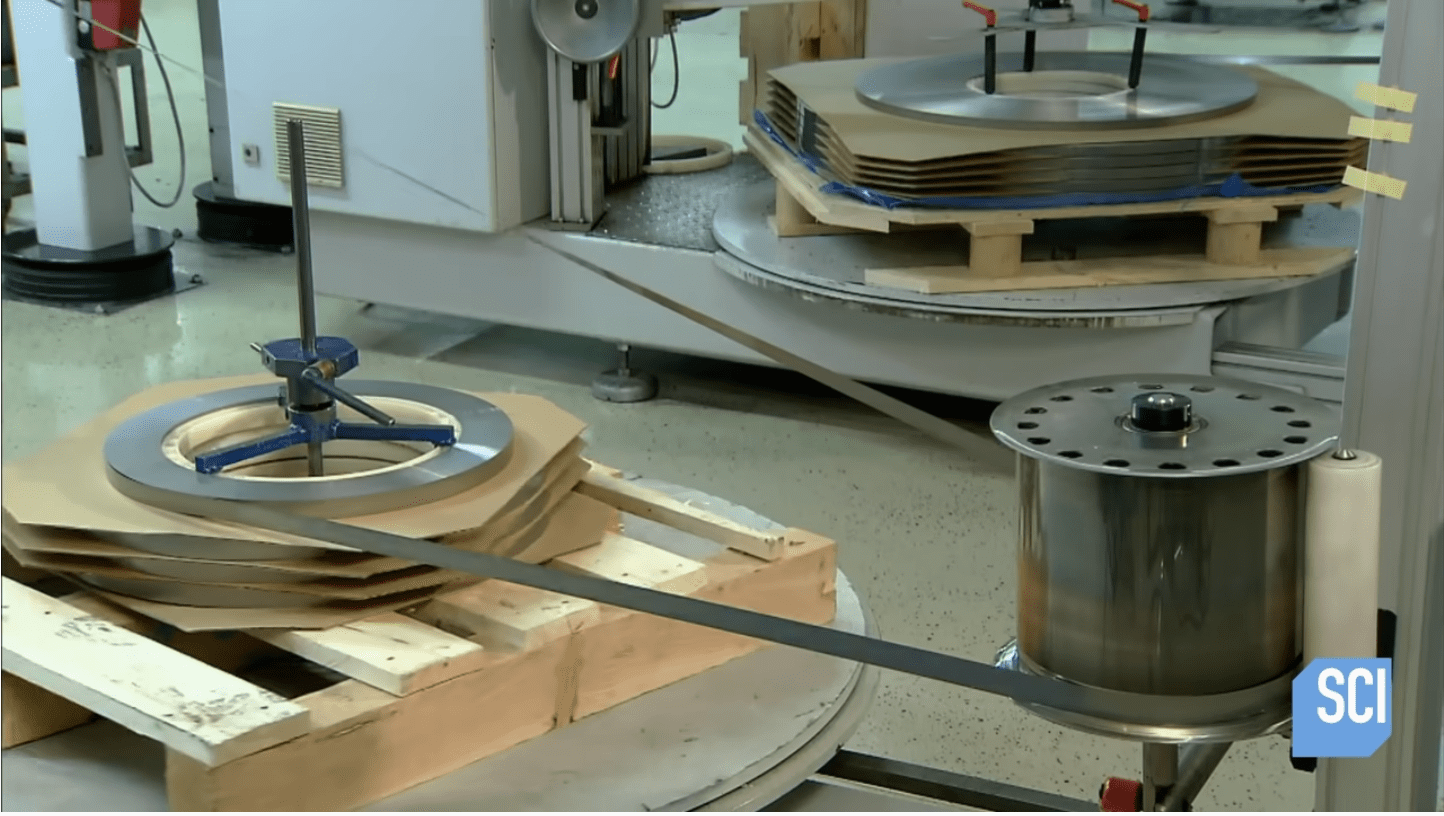

Image Credit: YouTube

Apparently, we’ve always been a bit annoyed at all that growing hair.

“Cavemen sharpened pieces of flint and used them to shave their facial hair.

Modern man can simply go purchase a pack of razor blades for his shaver.”

Image Credit: YouTube

When you go to the store and stand in the personal care aisle, there are so many choices – but if you look closely, the majority of them boil down to exactly the same design with a different colored label.

Image Credit: YouTube

“They’re paper-thin yet sharp enough and strong enough to cut through the coarsest beard.

Razor blades are made from a stainless steel strip that’s a mere four one-thousandths of an inch thick.”

Pretty crazy when you put it that way, right?

The process begins with a single strip of blade that is cut, heated, cooled, and then reheated to ensure the metal is as hard as possible.

Image Credit: YouTube

Then, the strip is branded and put through a grinding and polishing machine that creates the sharp double edges.

It also separates the blades from one another before the process is complete.

Before those blades go into a package and end up on a shelf, the individual blades are tested and coated for quality.

There are a lot more steps than I would have imagined – and a lot more than the cavemen went through, most likely – but I’m willing to bet people today get a lot closer, cleaner, and less dangerous shave, too.